The longer lasting, most affordable, completely sustainable, planter arm rebuilding solution

Attn: crop producers:

Trade your planter maintenance headaches for the freedom of superior longevity while retaining OEM compatibility.

Exchange your worn-out parallel arms for rebuilt ones.

It’s as easy as 1-2-3

1. Order

Order our affordable rebuilt parallel arms – they are better than the originals.

2. Replace

Replace the old arms on your planter with our upgraded ones.

3. Return

Using the same shipping container, ship back your old ones at no charge and get a credit for the cores.

A vastly improved

Parallel arm design

ParallelArmExchange.com is a service created by a Midwestern farm family that was frustrated with poor OEM design which led to excessive planter maintenance. We improved upon the original John Deere, Kinze, CNH, etc. designs to produce a superior, precision machined product.

And since we exchange rebuilt arms for old, you get a much lower net cost vs purchasing new, and recycling the old iron is an environmentally sustainable approach. It’s a win-win.

Get rid of slop and chatter in your planter parallel arms today! Order our Parallel Arm Exchange. It’s an intelligently designed, sustainable, cost and maintenance-saving solution for crop producers across the country.

Located in Remington Indiana, our product is remanufactured in the USA by farmers, for farmers.

Before

We start from worn OEM planter parallel arms that previous farmer customers exchanged for our rebuilt ones.

After

From that we repaint, precision mill a larger hole, and press in a hardened sleeve and bushing.

Superior engineering

How we improve planter parallel arms

Our design improvements fix the root wear issue resulting in superior longevity. We guarantee these will last longer than the originals.

OEM planter parallel arms are designed with a bushing that rubs against the housing on the arms, with the idea that when they would wear out, you would just replace the bushings. However, the bushings that they use are harder than the parallel arm housings themselves. Because of this, instead of the bushing taking the wear — the housing does instead. Over time it becomes egg shaped. This means that oftentimes, the entire arm needs to be replaced instead of the parts which were originally intended to be replaceable.

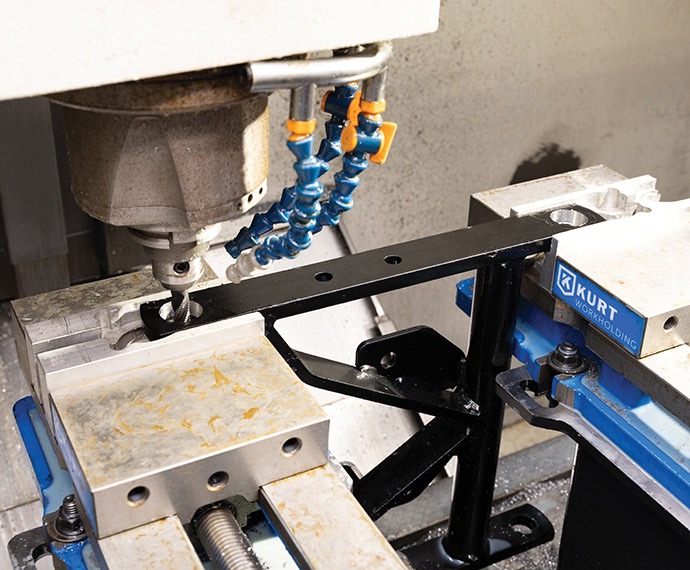

Our solution is to take these worn parallel arms and use our CNC machine to precisely mill out a larger hole into which we press a high-strength, heat-treated hardened sleeve. Inside of that goes a high-wear bushing. This bushing is much stronger than OEM bushings but slightly softer than our sleeve, meaning the bushing will wear first, as it should.

Our rebuilt arms significantly extend the life of planters and improve operational efficiency without the need to purchase entirely new equipment. It also reduces the long-term maintenance costs — and hassles — for grain producers.

The transformation

Going from left to right, you can see the starting worn-out parallel arm.

We first repaint it to match, then mill it with our CNC machine, add the hardened steel sleeve, then add the long-lasting bushing.

On the right is the finished, rebuilt parallel arm, ready to exchange!

FAQs

Frequently asked questions

Here are some common questions about our company.

Any crop producer who does not enjoy planter maintenance and cares about consistent seed placement and depth (which = higher yields). OEM parallel arms wear quickly. You can either replace the entire arm (expensive and does not fix the root issue), buy a kit and rebuild them yourselves (which is a total pain) or exchange your worn out arms for our rebuilt ones which offer an improved, longer lasting bushing and sleeve design.

When the used arms are ready to return, place them in the same crate that they were shipped in. At this point, let us know that they are ready. We will line up the return freight and send you a document to give to the semi driver when they come to pick them up.

Once we receive them, we will do an inspection on the arms and determine what condition they are in and proceed to send a reimbursement check for all that we are able to rebuild.

We do not charge for the return freight.

As long as you live in the lower 48, we can ship our rebuilt parallel arms to you. You ship back your old ones to us for a credit, using the crate we sent, postage paid.

It depends. Since we source our material from farmers who send back their worn arms, shipping times vary. (We do try to keep additional stock to allow us to bridge busy times.) Once you give us your downpayment, we’ll contact you with an estimated completion time. If we have the arms in stock, we make our best attempt to ship the new ones out within a week. Otherwise if it is longer than that, we will get in contact with you to discuss.

The parallel arm exchange is a solution developed by Solid Rock Ag Solutions, a service-oriented Precision Planting plus other short-lines dealer in northwestern Indiana. Started by a five-generation farm family, Solid Rock Ag has grown into a multi-faceted precision farming consultant providing a wide variety of performance-enhancing solutions for farmers. Working everyday with crop producers, we see problems and find solutions. Sometimes, if nobody provides a suitable solution, we create one ourselves. Such is the case with Parallel Arm Exchange.

The kits come with bushings which are compatible with the OEM hardware. If the bolts are kept tight, the wear surface should only actually be on the bushings themselves. We do not want to charge for unneeded materials, therefore, we do not include hardware as standard. If you wish to replace hardware, you can order this in our store as a separate line item.

The general rule of thumb is to replace the arms when there is 1/2” or more play when you lift up and down on the rear of the row unit. if someone is using an Automatic Hydraulic Downforce system, we generally recommend replacing them a little quicker since these systems are using a load cell to control them, and the more vibrations that the row unit has, this will diminish the performance of the downforce system.

A carbon alloy steel which is hardened and given a protective coating in order to protect against corrosion.

We are very optimistic about the wear life on this kit. We have customers with over 1000 acres per row of wear on this system, and as of now, we have not yet had a single customer need to replace a bushing or sleeve due to wear. However, when it does eventually wear, because of the bushing design it should be only the bushing at first that needs to be replaced. In theory the sleeves will also wear eventually, however these are also replaceable. So as with our solution, you should never have to replace your arms again.

Artwork credits: Wooden box icon created by DinosoftLabs, Order icon created by Talha Dogar, Wrench icon created by Prosymbols. All Flaticon